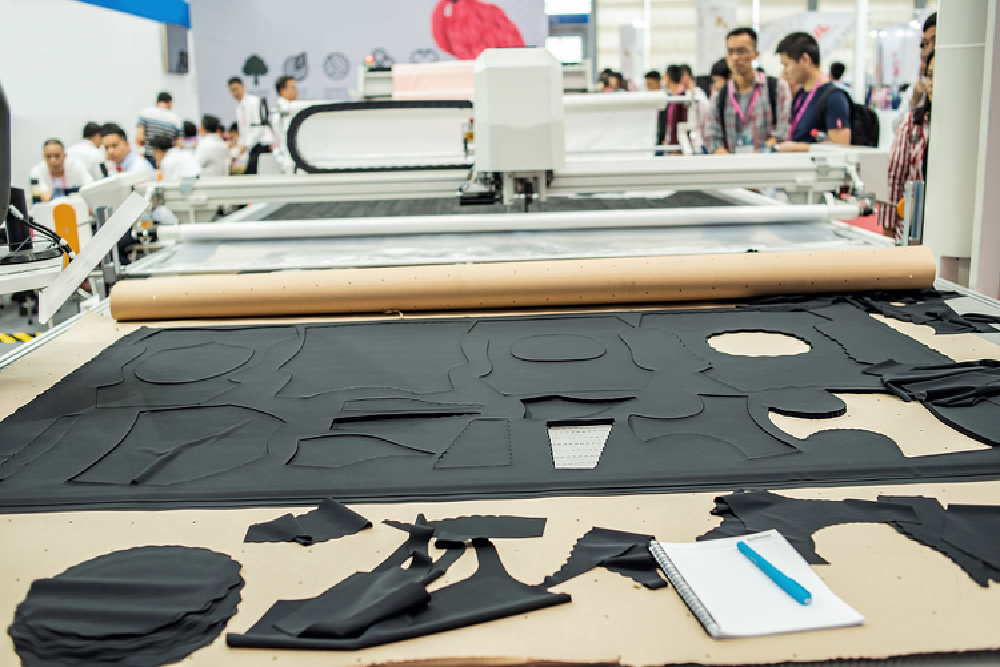

Problem: Cutting fabrics in the apparel, automotive seating, and upholstery industries is time-consuming and labor-intensive.

Agitation: Traditional manual cutting is inefficient, inaccurate, and difficult to meet the needs of mass production.

Solution: Auto cutting machines have emerged, which can efficiently and accurately complete cutting tasks, freeing hands and improving productivity.

An auto cutting machine is a device that uses computer control to automatically cut various flexible materials according to a preset program. It is mainly divided into two types: multi-layer cutting machines and single-layer cutting machines, each suitable for different production scenarios.

The advancement of cutting technology has undoubtedly brought good news to the manufacturing industry. However, facing a wide variety of automatic cutting machines on the market, how should we choose?

How many kinds of auto cutting machines are there?

Problem: Facing a dazzling array of automatic cutting machines, is your choice paralysis acting up again?

Agitation: Not understanding the characteristics and scope of application of different types of cutting machines can easily lead to blind purchases and waste of resources.

Solution: Understand the classification of automatic cutting machines, and choose the most suitable "cutting artifact" according to your own needs.

There are two main types of automatic cutting machines: multi-layer cutting machines and single-layer cutting machines. Multi-layer cutting machines can cut multiple layers of material at one time, which is highly efficient; single-layer cutting machines focus more on accuracy and flexibility, and are suitable for small-batch, personalized production.

Multi-layer Cutting Machine vs Single-layer Cutting Machine

| Feature | Multi-layer Cutting Machine | Single-layer Cutting Machine |

|---|---|---|

| Cutting Layers | Multiple layers (dozens or even hundreds of layers) | Single layer |

| Cutting Speed | Fast | Relatively slow |

| Accuracy | Relatively low | High |

| Suitable Scenarios | Large-volume, simple-design orders (such as: ordinary T-shirts, underwear, etc.) | Small-batch, complex-design, high-demand orders (such as: plaid shirts, custom clothing, etc.) |

| Advantages | High efficiency, low unit cost | High precision, strong flexibility, can achieve personalized customization |

| Disadvantages | Relatively low accuracy, not suitable for complex designs | Relatively low efficiency, high unit cost |

| Common Brands | GERBER, LECTRA, BULLMER, EASTMAN, MORGAN, IMA, FK | ZUND, ATOM, iEcho, RUIZHOU, JINWEI |

| STAK Parts Support | We STAK provide accessories for the above-mentioned brands of multi-layer cutting machines, such as bristle blocks, blades, grinding parts, etc. | We STAK also provide accessories for the above-mentioned brands of single-layer cutting machines, such as bristle blocks, blades, grinding parts, etc. |

From my personal experience, the key to choosing which cutting machine is your production needs. If you mainly produce large quantities of products with simple designs, then a multi-layer cutting machine is undoubtedly a more economical and efficient choice. But if you are pursuing personalization, high quality, or often need to deal with complex patterns (such as the alignment of plaid shirts), then a single-layer cutting machine can meet your needs.

What are the famous brands of multi-layer cutting?

Problem: Want to buy a multi-layer cutting machine, but don't know which brands are reliable?

Agitation: There are many cutting machine brands on the market, and the quality is uneven, so you are worried about buying inferior products.

Solution: Choose a well-known brand, the quality is guaranteed, and the after-sales service is also more complete.

Famous brands of multi-layer cutting machines include: GERBER, LECTRA, BULLMER, EASTMAN, MORGAN, IMA, FK. These brands enjoy a high reputation in the industry, and their product quality and technical level are in a leading position.

Multi-layer Cutting Machine Brand Overview

| Brand | Country | Features | STAK Parts Support |

|---|---|---|---|

| GERBER | USA | Technologically advanced, high market share | ✔️ |

| LECTRA | France | Stylish design, easy to operate | ✔️ |

| BULLMER | Germany | Sturdy and durable, stable performance | ✔️ |

| EASTMAN | USA | Cost-effective, wide range of applications | ✔️ |

| MORGAN | Italy | Innovative design, attention to detail | ✔️ |

| IMA | Italy | High degree of automation, high production efficiency | ✔️ |

| FK | Italy | Advanced technology, customized services | ✔️ |

| Oshima | Japan | A Taiwan company renowned for its outstanding quality. | ✔️ |

| Takatori | Japan | A Japanese enterprise guided by cutting-edge technology. | ✔️ |

It should be noted that GERBER is now owned by LECTRA. These brands of multi-layer cutting machines are widely used in apparel, automotive seating, upholstery and other industries. As an employee of STAK, I can proudly say that our company provides accessories for all of the above brands of multi-layer cutting machines, including bristle blocks, blades, grinding parts, etc. No matter which brand you choose, STAK can provide you with high-quality accessory support.

What is the famous brand of single-layer cutting?

Problem: Want to buy a single-layer cutting machine, but don't know which brands are good?

Agitation: There are relatively few brands of single-layer cutting machines, and the choices are limited, so you are worried about not finding the right one.

Solution: Understand the mainstream brands, compare their characteristics and advantages, and choose the one that suits you best.

Famous brands of single-layer cutting machines include: ZUND (Switzerland), ATOM (Italy), iEcho (China), RUIZHOU (China), JINWEI (China). These brands have their own strengths in the field of single-layer cutting to meet the needs of different users.

Multi-layer Cutting Machine vs Single-layer Cutting Machine (Detailed Comparison)

| Feature | Multi-layer Cutting Machine | Single-layer Cutting Machine |

|---|---|---|

| Working Principle | The multi-layer material is compacted by the presser foot, and the blade moves up and down for cutting | The material is laid flat on the worktable, and the blade or laser head cuts along the preset path |

| Cutting Layers | Multiple layers (usually dozens of layers, even hundreds of layers) | Single layer |

| Cutting Speed | Fast (because multiple layers are cut at once) | Relatively slow (because only one layer is cut at a time) |

| Accuracy | Relatively low (because there may be slippage or deformation between multi-layer materials) | High (because the material is laid flat, there is no interlayer interference) |

| Suitable Materials | Various fabrics, leather, composite materials, etc. | Various fabrics, leather, paper, film, foam, etc. |

| Application Scenarios | Large-volume, simple-design clothing, home textiles, automotive interiors, etc. | Small-batch, complex-design, high-demand clothing, luggage, advertising, packaging, etc. |

| Advantages | High efficiency, low unit cost, suitable for large-scale production | High precision, strong flexibility, can achieve personalized customization, suitable for small-batch, multi-variety production |

| Disadvantages | Relatively low accuracy, not suitable for complex designs, long material change time | Relatively low efficiency, high unit cost, not suitable for large-scale production |

| Vision Alignment | Usually not available | Some models are available, which can achieve accurate pattern alignment (such as plaid, stripes, etc.) |

Which cutting machine to choose depends on your specific needs. If your order volume is large and the design is simple, a multi-layer cutting machine is a more economical choice. If your order volume is small, the design is complex, or the accuracy requirements are high, a single-layer cutting machine is more suitable for you.

Which kind of machine is better for cutting fabric?

Problem: When cutting fabrics, should I choose a multi-layer cutting machine or a single-layer cutting machine?

Agitation: It is difficult to choose which cutting machine is more suitable for your fabric and production needs.

Solution: Comprehensively consider factors such as fabric characteristics, order volume, design complexity, etc., and choose the most suitable cutting machine.

There is no absolute "better", only "more suitable". Choosing which cutting machine depends on your fabric characteristics, order volume, design complexity, and other factors. If the order volume is large and the design is simple, a multi-layer cutting machine is more efficient; if the order volume is small, the design is complex, and the requirements are high, a single-layer cutting machine is more accurate.

Cutting Machine Selection Guide

| Factor | Multi-layer Cutting Machine | Single-layer Cutting Machine |

|---|---|---|

| Order Volume | Large | Small |

| Design Complexity | Low | High |

| Accuracy Requirement | Relatively low | High |

| Fabric Characteristics | Suitable for various common fabrics | Suitable for various fabrics, especially suitable for fabrics that are easily deformed and slippery |

| Special Needs | None | May require vision alignment (such as cutting plaid, striped fabrics) |

| Budget | Relatively low | Relatively high |

| Production Efficiency | High | Relatively low |

For example, if you want to produce a large number of ordinary T-shirts, then choosing a multi-layer cutting machine is more cost-effective. But if you are making a plaid shirt and require the pockets and front placket to be aligned, then you must use a single-layer cutting machine and use its vision alignment function to achieve precise cutting.

The automatic cutting machine is an important tool in modern manufacturing. Choosing the right cutting machine can significantly improve production efficiency and product quality. Both multi-layer cutting machines and single-layer cutting machines have their own unique advantages and application scenarios. The key is to make an informed choice based on your own needs. Hope this article can help you better understand automatic cutting machines and find the "cutting artifact" that suits you best.