Are you puzzled by the automatic cutting machine market? It’s growing fast with endless possibilities. I’ll walk you through its details.

Automatic cutting machines are single-layer or multi-layer, used in apparel, auto seating, bags. Prices drop, automation boosts market size.

The automatic cutting machine market is exciting. I’ll dive into its types, uses, and trends. You’ll want to read on for more.

What Types of Automatic Cutting Machines Exist?

Curious about cutting machine types? Single-layer and multi-layer machines serve different needs. I’ll explain them clearly.

Automatic cutting machines are single-layer or multi-layer. Single-layer suits precision; multi-layer fits mass production, with rapid market growth.

Single-Layer Machines

Single-layer machines excel in precise cutting, like leather for auto seats. I’ve seen them shine in high-end markets due to their accuracy.

Multi-Layer Machines

Multi-layer machines handle mass production, like apparel or seat fabrics. I notice they save time and boost efficiency, making them factory favorites. From 2020 to 2024, multi-layer sales grew faster, and I expect this to continue through 2031.

Market Trends

I think automation drives multi-layer machine adoption. Here’s a data comparison:

| Type | 2020 Sales | 2024 Sales | 2031 Forecast |

|---|---|---|---|

| Single-Layer | Steady | Growing | Moderate Growth |

| Multi-Layer | Rapid | High | Leading |

Where Are Automatic Cutting Machines Used?

Wondering where cutting machines apply? Their uses shape your choices. I’ll break down the key areas.

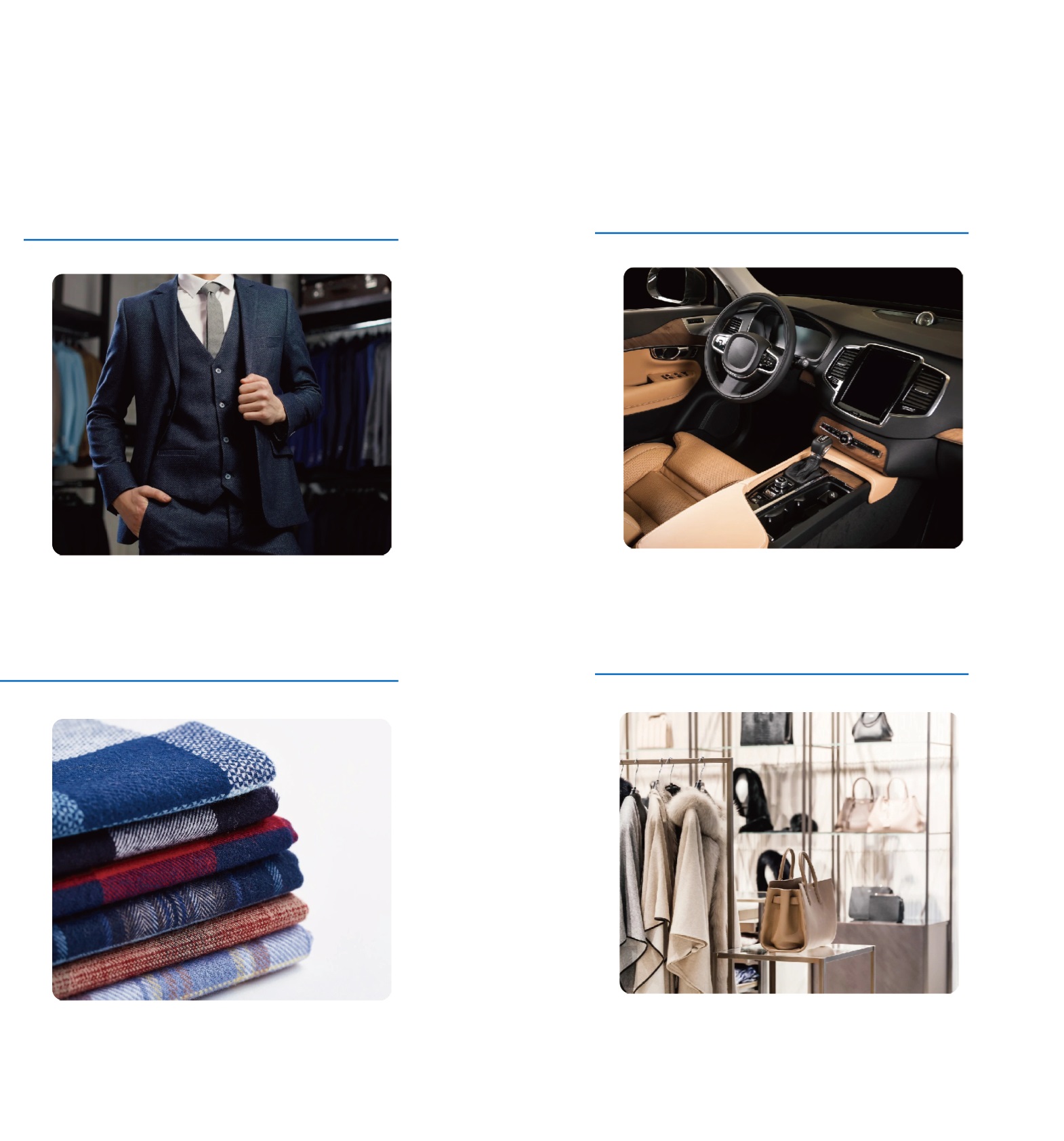

Automatic cutting machines serve apparel, auto seating, bags, and other industries. Apparel dominates; auto seating grows fast.

Apparel Industry

Apparel is the biggest market. I’ve seen factories use multi-layer machines to cut costs and speed up production.

Auto Seating

Auto seating grows with demand for luxury vehicles. I notice single-layer machines excel here for precise leather cuts.

Bags and Others

The bag market is expanding, and furniture also uses cutters. I believe automation widens their applications. Here’s the market data:

| Application | 2020-2024 Growth | 2024-2031 Forecast |

|---|---|---|

| Apparel | High | Sustained High |

| Auto Seating | Moderate-High | Rapid Growth |

| Bags | Moderate | Steady Growth |

What’s the Current State of the Cutting Machine Industry?

How’s the cutting machine market doing? You might want to know its status. I’ll share what I’ve seen.

The cutting machine market grows fast due to automation. Lower prices and tech improvements expand its size.

Current Status

I’ve watched the market thrive as factories embrace automation. Lower prices make cutters affordable for smaller businesses. My company, STAK, supplies parts for brands like Lectra and Bullmer, and demand is strong.

Industry Challenges

Technology evolves quickly, so factories must upgrade often. I think competition pushes brands to focus on service and part quality.

Market Data

The market grew from $1 billion in 2020 to $1.5 billion in 2024. I predict it’ll hit $3 billion by 2031.

| Year | Market Size (USD Billion) | Growth Rate |

|---|---|---|

| 2020 | 1.0 | - |

| 2024 | 1.5 | 50% |

| 2031 | 3.0 | 100% |

What’s the Future of Automatic Cutting Machines?

What lies ahead for cutting machines? You’re probably curious about their trajectory. I’ll give you my take.

Cutting machines will get smarter with AI. Falling prices and automation needs will keep the market growing.

Tech Advances

I’ve noticed machines adopting AI and data analytics for better precision and efficiency. I think this will make production smarter.

Market Drivers

Automation pushes cutter adoption. I believe apparel and auto seating will keep expanding the market.

Future Outlook

Lower prices mean more factories can afford cutters. I expect the market to double by 2031. Here’s the forecast:

| Trend | 2024 Status | 2031 Outlook |

|---|---|---|

| Technology | Automation | AI + Smart Systems |

| Market Size | $1.5 Billion | $3 Billion |

| Applications | Apparel + Seating | More Industries |

The automatic cutting machine market grows fast with automation and lower prices. Single- and multi-layer machines serve diverse industries with a bright future.